- This is a verified supplier can provide quality products and have passed the Business License Check.

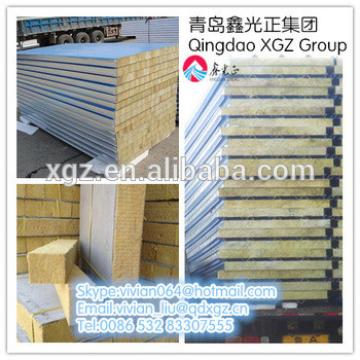

Home>Products>Construction building materials>Rockwool sandwich panel for roof and wall

Rockwool sandwich panel for roof and wall

- 2000 Square Meter/Square Meters

- US $20 - 800/ Square Meter

- 15 days

- paypal,UnionPay, Visa/MasterCard, Amex, Discover,T/T

- 500000 Square Meter/Square Meters per Month

-

2020-07-10 09:46:19

Welcome to my shop! Glad to serve you! Please send your question!

2020-07-10 09:46:19

Welcome to my shop! Glad to serve you! Please send your question!

Product Details

| Standard: | ISO | Usage: | Wall Panel | Color: | Sky blue and Gray white |

Product Description

Lightweight Prefab Fire-proof Rockwool Sandwich Wall Panel for external wall

Product introduction:

Light weight insulation wallboard batten use fiber cement board or calcium silicate board production equipment and technology and inorganic insulation board production equipment,finish only one process,it is divided double layer panel and core material and no core material of the double panel battens,the core material is mainly composed of silicate cement and EPS foam and adhensive,fiber combinations.Its mainly used as interior wall partition and exterior wall substrate,instead of clay brick and color steel plate and other building materials.

Main features:

1.Excellent fireproof,Class A1 non-combustible sheet,75mm wall fire resistance can reach to more than 3 hours.

2.Excellent strength,and light weight.

3.Good stability, no deformation,and low shrinkage rate.

4.Good impact resistance,compressive strength,anti-tensile and anti-breaking performance.

5.Waterproof,moisture-proof,anti-insect,and mildew-proof.

6.Green environmental,heat insulation, thermal insulation.

7.Versatility, surface decoration.

8.Affordable,convenient construction.

Technical index:

Item | National standard | Inspection conclusion | ||||

75mm | 90mm | 120mm | 75mm | 90mm | 120mm | |

Impact resistant property, times | ≥5 | ≥5 | ≥5 | ≥8 | ≥10 | ≥15 |

Bending load, self-multiples | ≥1.5 | ≥1.5 | ≥1.5 | ≥3 | ≥4 | ≥5 |

Compressive strength, Mpa | ≥3.5 | ≥3.5 | ≥3.5 | ≥5 | ≥5 | ≥5 |

Softening coefficient | ≥0.80 | ≥0.80 | ≥0.80 | ≥1 | ≥1 | ≥1 |

Surface density,kg/m2 | ≤70 | ≤90 | ≤110 | ≤55 | ≤70 | ≤85 |

Water content rate,% | ≤12/10/8 | ≤10/9/7 | ||||

Dry shrinkage value, | ≤0.6 | ≤0.6 | ≤0.6 | ≤0.45 | ≤0.5 | ≤0.5 |

Hanging force,N | ≥1000 | ≥1000 | ≥1000 | ≥1200 | ≥1300 | ≥1500 |

Sound insulation capacity in the air,dB | ≥30 | ≥35 | ≥40 | ≥35 | ≥40 | ≥45 |

Fire resistant limit,h | ≥1 | ≥1 | ≥1 | ≥2.5 | ≥3 | ≥4 |

Thermal conductivity coefficient, b/w/m.k | ≤1.0 | ≤1.0 | ||||

Radioactivity | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 |

IRa | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 |

Ir | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 |

Specifications:

Specification | Thickness(mm) | Length(mm) | Width(mm) | Reference weight(kg/m2) | Allowed tolerance(mm) |

Series of 60 | 60 | 3000 2270 2440 | 610 | 35±5 | Length±5 Width±2 Thickness±1 Flatness±1 |

Series of 75 | 75 | 42±5 | |||

Series of 90 | 90 | 49±5 | |||

Series of 120 | 120 | 55±5 | |||

Series of 150 | 150 | 81±5 | |||

Notes | Also can be customized according to clients requirements. | ||||

Light weight composite sandwich wall panels installation process:

1.Put wire,transport board in place,pop-up or down the wall plate and gauge double in the respective axis mount.

2.Any use of drilling to cut according to wall plate specifications.

3.Put cement binder and wall board in foundation.

4.Put cement binder,two pieces of the tenon on one side cement to wipe polymer mortar on any tongue and sides.

5.Installation,firstly prepare for the installation of plate moved into connection location,wall correction with a crowbar,use force tightly,to let polymer mortar extrusion from the joints in high spirits.

6.Adjustment,use wood wedge to bit into the bottom of the wall plate so that it adjust vertical formation.

7.Correction,fix,use more than 2m or 2m guiding rule to check vertical,flat correction.

8.Grout,fill the pulp,use polymer mortar to infill and flatness after correcting the wall body,use polymer mortar to fill the gap size up or down.

9.Fixed,upper part of wall panels with Φ6mm or Φ8mm steel reinforce in the middle of walls by 45 degrees to bit into,the bottom with “7-shaped”ribbed steel,one head is bitten into concrete base,the other head is bitten into the wall plate.

Export Markets : North America, South America, Eastern Europe, Southeast Asia, Africa, Oceania, Mid East, Eastern Asia, Western Europe

Contact Us

- Phone(Working Time)

Product Categories

- Steel Structure Workshop

- Steel Structure Materials

- portable emergency shelter

- EPS

- External Wall Insulation Board

- Calcium Silicate board

- CONTAINER OFFICE

- Putty

- Container House

- Crane Bridge

- template

- CONTAINER RESTAURANT

- MODIFIED SHIPPING CONTAINER

- prefab steel house

- Steel Structure warehouse

- Recommended Products

- aluminum composite panel

- mat

- prefab house kits

- Construction building materials

- DOORS AND WINDOWS

- Prefab House/Villa

- Metal Processing Product

- Crane

- Steel Garage/Carport

- steel structure villa

- Steel Structure Hangar

- Sandwich Panel

- Steel Structure Buildings

- Poultry House

- prefab villa

- CONTAINER LIVING ROOM

Ecomonic cladding material EPS Sandwich Panel

Ecomonic cladding material EPS Sandwich Panel Building materials B05 AAC/ALC wall and roof panel

Building materials B05 AAC/ALC wall and roof panel XGZ Environmental protection and energy saving prefabricated house as china supplier

XGZ Environmental protection and energy saving prefabricated house as china supplier China XGZ lowest metal roofing sheet price

China XGZ lowest metal roofing sheet price XGZ best structural steel building materials

XGZ best structural steel building materials